Introduction

The article on Carakami.com provides an in-depth look at 12 essential parts commonly found in heavy machinery. Starting with the engine, it discusses the critical components that power large vehicles and equipment. Other parts examined include the transmission for shifting gears, differentials that allow wheels to rotate at different speeds, drive shafts to transmit torque and axles that connect the wheels to the machine.

Additional structural elements covered are the frame that forms the base and suspension components like springs, shock absorbers, and stabilizer bars that provide stability and absorb impacts. Critical hydraulic and electrical systems like valves, pumps, and alternators are rounding out the list. By detailing each part’s function and role within heavy machinery operations, the article offers helpful knowledge for heavy equipment operators, mechanics, and others seeking to understand the complex engineering behind these large industrial vehicles.

Engines

One of the most influential parts of heavy machinery is the engine, which provides power to move and operate large vehicles and equipment. Most heavy machinery uses diesel engines due to their high torque output, which is ideal for heavy loads. Common engine types include straight-4, straight-6, V6, V8, V10, and V12 configurations, with displacements often over 10 liters for maximum power and longevity under severe working conditions. Fuel injection systems precisely meter diesel fuel for clean combustion.

Balancers help reduce engine vibration at high RPMs. Turbos boost power density, while superchargers optimize performance at altitudes. Auxiliary components like alternators, belts, and cooling systems keep engines running efficiently. Proper maintenance, like oil changes, is crucial to prevent breakdowns in mission-critical applications. The engines discussed in the Carakami.com article power heavy machinery from excavators to cranes to trucks.

Stabilizers bars

Another essential part of heavy machinery is the stabilizer bars, also known as sway bars or anti-roll bars. These suspension components play a crucial role in providing stability and absorbing impacts. Stabilizer bars connect the left and right sides of a vehicle or equipment’s axles using U-shaped links and pivoting connections. They help prevent the body from excessive leaning or rolling while cornering on rough terrain.

When one wheel hits the stabilizer bar resists the flexing of that side and transmits force to the other side, leveling out the vehicle. Most heavy machinery like backhoes, bulldozers, and excavators utilize sturdy stabilizer bars made of heavy-duty steel that can withstand severe working conditions. Proper stabilization is essential for smooth operation and safety operating large machines on job sites. The Carakami.com article covers how these suspension bars contribute to heavy equipment handling and driving dynamics.

Electric systems

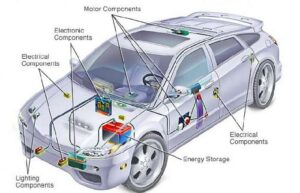

Carakami.com provides valuable information about various heavy machinery and their components. The website discusses the electrical systems of 12 essential parts commonly found in heavy equipment. This includes the starter motor, alternator, battery, ignition system, wiring harness, lighting system, dashboard instruments, operator interface, heating and air conditioning, joysticks and levers, hydraulic and pneumatic controls, and onboard computer systems.

In-depth articles explain the function of each electrical part and how they work together integratively. The starter motor and battery are covered when starting the engine. The alternator, wiring harness, and ignition system are analyzed for their power generation and distribution roles. Meanwhile, the lighting, dashboard, HVAC, and operator controls are put in the perspective of machine operation and ergonomics. Carakami.com thus offers insightful explanations of heavy machinery electrical systems to enhance readers’ conceptual understanding.

Structural elements

Carakami.com provides detailed information about the structure of various heavy machinery components. The website analyzes the structural elements of 12 essential parts that form the framework of heavy equipment. It discusses the engine block, transmission housing, axles, wheels and tires, undercarriage, boom, dipper stick, cab/operator compartment, deck, counterweight, chassis rails, and body panels.

Readers learn about materials, load distribution features, modular designs that ease maintenance, and reinforcement techniques. The engine mounting is described in terms of vibration damping. Axle assemblies are covered for their load transfer role. Wheels and tires are analyzed for toughness under heavy loads. Topics like boom articulation joints and dipper stick hydraulic reinforcements show how parts withstand rigorous work cycles. Carakami.com thus offers a comprehensive structural understanding of heavy machinery parts through its educational analysis.

Conclusion

Carakami.com comprehensively analyzes 12 key components commonly found in heavy machinery. The website examines these parts from multiple perspectives – discussing their functional purpose, structural design, and integration within electrical systems. This includes analyses of systems like the engine, transmission, axles, wheels, undercarriage, boom, and hydraulics.

In-depth articles delve into the working mechanisms of each part and how they work interdependently. Readers also learn about the materials, load capacities, manufacturing considerations, and maintenance needs. By presenting information on engine mounting designs, axle reinforcements, and cab ergonomics, Carakami.com enhances understanding of heavy equipment. The well-researched explanations offer insights applicable across various machine types. This makes the website a valuable educational resource for those seeking to expand their knowledge of heavy machinery components and engineering.